procedure of bending test|four point bending test procedure : purchase The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of .

WEBRelacionamento Brasil com o VIVALOCAL Brasil Brasil: mais de 400,000 CLASSIFICADOS GRÁTIS. Relacionamento leva só 2 cliques!

{plog:ftitle_list}

web31 de dez. de 2023 · A participação no Viva Sorte é descomplicada e acessível a todos. Basta estar cadastrado e adquirir um título para concorrer aos prêmios do sorteio em .

welding bend test procedure pdf

The procedure for conducting a bend test using a Universal Testing Machine (UTM) can be broken down into the following steps: Test Preparation: This involves preparing the test specimen according to the relevant standards (like ASTM or ISO).

A bending test (bending tensile test) is a method of testing materials for their bending strength and other important properties. Destructive materials testing is used for plastics, fiber-reinforced plastics (FRP), metals and ceramic .

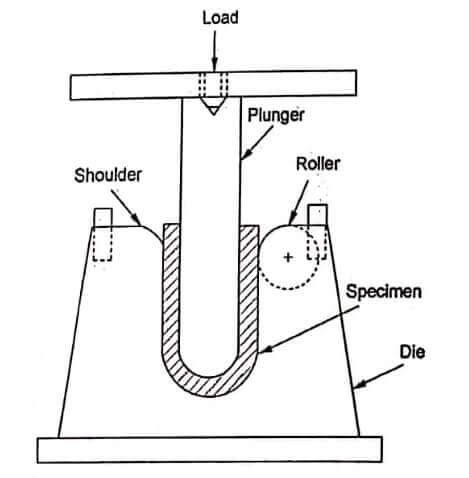

Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force . Bending test is used to determine the tensile strength of brittle materials that are generally difficult to test in uniaxial tension due to cracking in the grips. The most common .

The 3-point bending test, also known as flexural testing or transverse beam testing, measures the behaviour of materials in a simple beam loading geometry. This type of testing provides .The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of . Universal testing machines equipped with bend fixtures are used to calculate flexural modulus, flexural strength, yield point, and more. This post discusses the equipment required for common .Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of .

transverse vs longitudinal bend test

A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials. This testing methodology involves subjecting a specimen to a .Bend tests are conducted to determine the ductility or strength of a material. This article discusses the different bend tests with emphasis on test methods, apparatuses, procedures, .Unlike the four-point bending test, the three-point bending test can produce a single crack in a certain position that has a notch. Kanellopoulos et al. [69] and Qureshi et al. [68] used three-point bending tests to assess the healing potential of concrete incorporated with mineral admixtures and encapsulated glass tubes to determine the load .

Test setup. In the bending flexural test, a specimen is loaded under uniaxial bending stress (tension and compression) in order to obtain information on the bending behaviour of materials.Especially brittle materials .The Bending Test Materials testing is a fundamental part of Materials Science and Engineering, in understanding the . Testing Procedure: Ensure safety goggles are worn at all times during the experiment. Be careful of sample fragments flying when the sample fractures.The four-point flexural test provides values for the modulus of elasticity in bending, flexural stress, flexural strain and the flexural stress-strain response of the material. This test is very similar to the three-point bending flexural test.The major difference being that with the addition of a fourth bearing the portion of the beam between the two loading points is put under maximum .

section of side 40 mm. The bar was placed on the bending support at the minimum span and load–displacement curves were obtained. The displacement rate was 1.4 mm/min and the maximum load was approximately 7000N”[1]. Fig. 2 shows the testing configuration. Fig. 1. Load-displacement curve of an indentation test . Fig. 2. Example of .

ASTM flexural test refers to testing procedures governed by ASTM standards, such as ASTM D790 for plastics, ensuring consistent and comparable results across laboratories. What is the difference between a flexure test and a bend test? While both assess a material’s behavior under bending, the flexure test quantifies specific properties like .It tests the ability of unreinforced concrete beam or slab to withstand failure in bending. The results of flexural test on concrete expressed as a modulus of rupture which denotes as (MR) in MPa or psi. The flexural test on concrete can be conducted using either three point load test (ASTM C78) or center point load test (ASTM C293 . 4.1 The bend test shall be carried out in testing machines or presses equipped with the following devices: 4 b) 4 Bending device with two supports and a mandrel as shown in Fig. 1, Bending device with a V-block and a mandrel as shown in Fig. 2, and Bending device with a clamp as shown in Fig. 3. 1 FIG.

The bend test is specified in ASME section 9 and AWS D1.1 for welder testing & weld testing for performance & procedure qualification. 2. . FREE-BEND TEST FOR WELD TESTING. Free Bend Test measures the ductility of the weld metal in a butt joint in a plate or pipe in terms of elongation percentage. The thickness of the specimen is the same as .This article discusses the different bend tests with emphasis on test methods, apparatuses, procedures, specimen preparation, and interpretation and reporting of results. The types of bend tests discussed are bending ductility tests, bending strength tests (ASTM E 855), bend tests as per EN 12384 and JIS 3130, and computer-aided bending tests .

A 10-year follow-up evaluation about the effectiveness of school screening for scoliosis shows that Adam’s forward bend test has a sensitivity of 84.3%, a specificity of 93.44% for a cobb angle >10° but the authors of the study concluded that the forward bend test alone was ineffective for detecting scoliosis, owing to the high number of . In the case of orthotropic materials like wood or composites, transverse shear has an effect on the modulus determination by bending tests. A procedure based on three-point bending is proposed.

Tensile testing cannot be used to determine bendability, since these are different failure modes. Failure in bending is like other modes limited by local formability in that only the outermost surface must exceed the failure criteria.. ASTM E290 A-26, ISO 7438 I-8, and JIS Z2248 J-5 are some of the general standards which describe the requirements for the bend testing of metals.

four point bending test procedure

Bend Test Process and Procedure. The bend test requires using a mandrel with a diameter measuring at least four times the thickness of the sample. The sample with the coated surface is placed in a vise with the coating facing outward and bent over the mandrel until its two legs are parallel. Bend the specimen back and forth repeatedly through .A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials.This testing methodology involves subjecting a specimen to a .Flexural stress at break: The flexural stress at which a specimen breaks during a bend test. For some materials, the specimen breaks before a yield point, in which case the flexural strength equals the flexural stress at break. Test Method. .Three-point Bend Test procedure and working is derived from the theory of bending of the simply supported beam as explained above. To carry out the calculation of the test results after conduction of the 3-point bend test, one .

8 Procedure. 9 Interpretation of results. 10 Test report. . Cheong K. et al., ?Evaluation of the VDA 238-100 Tight Radius Bending Test using Digital Image Correlation Strain Measurement?, Int. Journal of Physics, Conf. Ser. 896 012075, (2017) [6]the bending procedure, including the heating/cooling cycle and post bend heat treatment, is determined by the pipe material, diameter, wall thickness, bend radius and the required properties after bending. Because of the many variables involved, the bending procedure should be determined by the fabricator. Pipe Fabrication InstituteBending strength is defined as a material's ability to resist deformation under load, it represents the highest stress experienced within the material at its moment of rupture. There are two types of bending tests. Three point bending test and four point bending test. In a three point bending test the area of uniformThe standard test specimens are not intended for concrete with steel fibres longer than 60 mm and aggre-gate larger than 32 mm. The procedure for casting of the specimens and filling of the mould is shown in Fig. 1. It . Bending test Final Recommendation. 580 Materials and Structures/Matériaux et Constructions, .

B1. Longitudinal Guided-Bend Test (See Part A1, section 7.6, Fillet Weld Root Bend Test.) 1. Scope 1.1 This section covers the bend testing of fillet welds. The standard gives the requirements for guided bend test specimen preparation, test parameters and testing proce-dures, but does not specify the requirements or accep-tance criteria.

The SCB test is defined in many world standards, e.g. EN 12697-44:2019, AASHTO TP 105-13, ASTM D8044-16, AASHTO TP 124-18 etc. The principle of SCB test is always the same and it is a three point bending of semi-circular specimen with defined notch on the bottom edge.Test Procedure. Insert the bending device in the UTM. Measure the width and depth of the wooden beam. Adjust the support for the required distance and clamp to the lower table. Fix the transverse test pan at the lower side of the lower cross head.Before performing the welding bend test, it is critical to complete the following fundamental procedures in filler metal preparation: Sample Extraction: Take representative samples from the welded connection, making sure they are large enough and shaped correctly for bending. The tensile test procedure involves attaching the sample to the testing machine and applying force until the material fractures. The results are typically recorded in a stress-strain diagram. The most important parameters measured in the test are the ultimate tensile strength, yield strength, and elongation at break.

Rotating bending test and reverse bend test. A special type of fatigue test is the rotating bending test, where a round specimen is subjected to an alternating bending stress in order to test bending fatigue strength. Due to the constant bending moment and rotation, the tensile and compressive stresses produced in the material change permanently.

cantilever bending test

universal testing machine rubber

WEBResults for : ruiva peituda. FREE - 8,640 GOLD - 8,640. Report. Mode. Default. Period. Ever. Length. All. Video quality. All. Viewed videos. Show all.

procedure of bending test|four point bending test procedure